As this article points out, the impact of the pandemic and the resulting economic disruption pointed out several major weak points in most current industrial/manufacturing ecosystems. When countries around the world struggled to provide even the most basic of needs, such as toilet paper and PPE gear, it's clear that industry just wasn't prepared for large-scale disruption.

As we've been discussing for awhile, foundational techniques and ideas can provide excellent starting points for making positive changes to your ecosystem - changes which will hopefully mitigate any similar disruptions that happen in the future. These are some of the most important elements to look into.

1. Manufacturing centers need to be diversified - and localized

Probably the #1 takeaway from the economic disruption of COVID-19 is that far too many industries had become over-reliant on global supply lines and manufacturing centers located on the other side of the planet. Once travel between China and other industrial centers became disrupted, the flow of goods slowed to a trickle.

Industry moved manufacturing overseas for the sake of cost savings, but those savings ended up being very costly in the long run. It's clear that there is a need for more diversified manufacturing and supply, with more production centers kept close to home so that global disruption won't completely wreck local distribution.

2. Industry 4.0 (4IR) technologies will help maximize production

So, if it's untenable to seek out the cheapest manufacturing centers, how can costs be kept low? Through the embrace of 4IR tech? Smart industrial technology such as automation, AI oversight, and deep data analytics will allow companies to make more, with less. Minimaxing factory output becomes far easier with Industry 4.0 technology, especially when they frequently allow companies to reclaim floor space and make their existing production lines that much more productive.

Plus, with a decade or so of investment and exploration of Industry 4.0 upgrades, we're starting to put together solid roadmaps of how companies can avoid common problems and see real returns on their upgrade investments. The Global Lighthouse Network is another great resource for companies looking to work together in adopting effective 4IR strategies.

3. Investing in education and training today will pay off tomorrow

Communications are another field which is being revolutionized, and that's a good thing for businesses looking to have a balanced approach to global business. It's easier than ever for companies to recruit and train technicians and other experts, even in foreign countries. For example, agricultural giant Caterpillar has had huge success with their Technicians For Africa program, enabling remote training and certification of techs in areas where Caterpillar has limited official physical presence. This allows them to provide technical support around the world, and is creating a 'breeding ground' of new workers who will be available whenever they further expand their African investments.

READ MORE: TECHNICIANS FOR AFRICA GETS BOOST FROM MANTRAC CATERPILLAR

LogicBay Enables Easy Global Training, Communication, and Collaboration

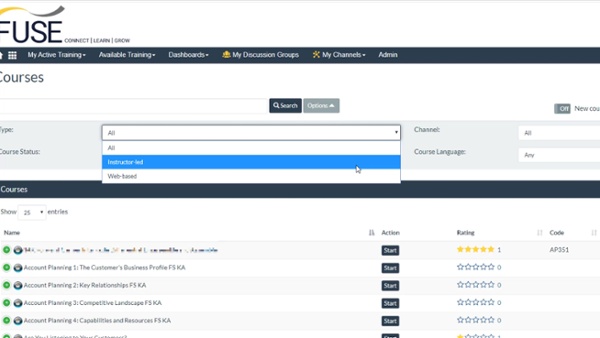

Our groundbreaking free-to-start platform FUSE is specifically designed to make it simple for companies to consolidate communications and training across their entire ecosystem - see video below! Whether you're looking to train workers overseas, or just want to enable easier training and certification of your domestic partners, FUSE provides all the tools you need in a simple platform that anyone can access.

Click here to claim your own free FUSE account, or contact us to learn more specifics about how FUSE can be integrated into your current training and certification plans.