More industry leaders are starting to advocate for major changes in how industrial operations do business - such as this recent editorial from Craig Hayman, the CEO of AVEVA, a subsidiary of Schneider Electric. His predictions for 2021 in industry line up almost exactly with our own discussions of the need for industry to adopt Industry 4.0 practices and digital ecosystems.

There are four elements and ideas that Industry needs to adopt if they're going to stay relevant - and it needs to be done sooner, rather than later. At this point, operations that continue to stick to older business processes are going to fall further and further behind.

1. Automation

According to Gartner, “By the end of 2024, 75 percent of enterprises will shift from piloting to operationalizing AI, driving a 5x increase in streaming data and analytics infrastructures.”

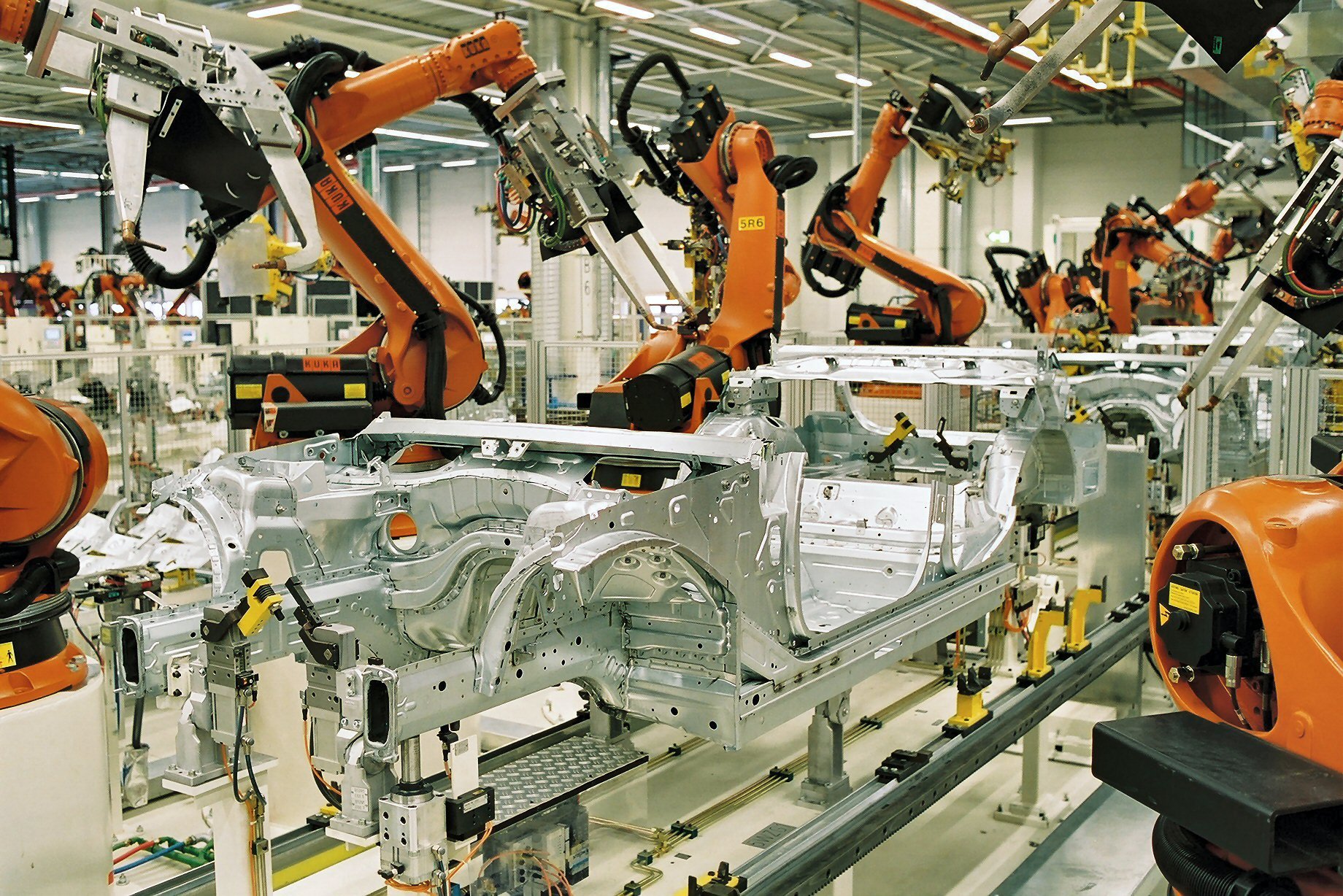

Just as the Third Industrial Revolution involved widespread use of "dumb" robots to improve assembly line efficiency while reducing manpower, in the 21st Century, "smart" automation and AI will be the next big step. Rather than programmable robots that simply repeat a few simple tasks over and over, modern automation systems can make complicated and contextual decisions while monitoring hundreds or thousands of individual metrics across an entire factory. Every valve, every gauge, every critical component can be monitored more closely and more reliably than human operators can manage, which will lead to reduced manufacturing costs alongside improved QC and tolerances.

The need for human oversight won't be eliminated entirely, of course, but it will be greatly reduced. Even in those cases, the AI will be able to alert human overseers faster when something does go wrong.

2. Digitization

Smart automation relies on one thing more than anything else: digital information. For a smart factory to work, every component needs to have some form of local connectivity, allowing the AI overseers to monitor conditions. In turn, this requires a robust and flexible digital infrastructure capable of handling large amounts of data, and ensuring a reliable flow of data between the machines and people who need access to it.

Such upgrades will be somewhat costly, but they'll pay off in the end because there's so much more that can be done with robust data streams.

3. Data storage and analysis

The operational data being gathered by Industry 4.0 automation systems isn't only for in-factory use. It will be a wealth of data to be mined for insights into new ways to streamline and improve workflows. Never before has it been possible for factory operators, and those in similar roles, to get such a low-level realtime look into the functioning of their factory.

This will require the adoption of cloud-based data storage and analytical solutions, but fortunately, cloud technologies are now mature and robust. Choose a good partner and your data will be safe for a long time to come.

4. Sustainability

The other thing enabled by this embrace of data-gathering and analysis will be improved sustainability. By having deep insights into every aspect of an industrial operation, those in charge will have better ability to make long-term plans. Supply lines can be planned out with flexibility in mind, and known possible disruptors can be foreseen and guarded against with even greater accuracy.

All of these elements add up to create industrial assets which are smarter, faster, easier to manage, and producing better-quality products. Businesses which embrace them will be best positioned to reap the benefits of a digital world going forward.

Need help making a change?

With the right technology, businesses can improve costs, boost efficiency and avoid costly mistakes. "The combination of digitization, automation and data driven insights, with a focus on sustainable business can be a key differentiator and a propelling force to help ensure businesses meet their goals of today and tomorrow."

If you're looking for inroads into Industry 4.0 upgrades or need qualified consultants with more than a decade of experience helping operations embrace the digital revolution, LogicBay is here. Our technology and services are built to meet manufacturing challenges head on. Contact us to learn more about our products and services!