More than a year after the start of the pandemic we're still seeing significant problems in manufacturing in shipping, with some industries - such as consumer electronics - predicting at least another year or two until things get back to normal.

This should be a wake-up call to any business with large-scale supply lines. This sort of disruption can't be allowed to happen again. Fortunately, new Industry 4.0 techniques, already being adopted before the outbreak, are making it easier to create supply lines which are more robust. By digitizing your supply lines and integrating Internet-of-Things oversight, you can create supply lines which are far more resilient - protecting your own business interests, while helping prevent another large-scale systemic disruption.

These are some of the most important elements to focus on

1. Connect everything to central cloud platforms

Step one is setting up a cloud platform that can centralize all your data, and then connecting all your subsidiaries to that platform. Then all the data will be in one place for easy analysis. For even better results, make the platform open and easy enough to implement that partner companies can also contribute data.

Ideally, you should be able to track every component in every product throughout its life cycle, from initial acquisition to final product. This will also have other long-term benefits. For example, if a particular faulty component is causing an excess of product complaints/returns, robust supply chain data tracking makes it far easier to identify the cause and prevent it from happening again.

2. Avoid data silos

Another critical element is ensuring that all relevant data is made available to everyone who needs it. This means keeping the data in a secured, yet open, format that anyone with proper permissions can access. This way, for example, individual sales outlets won't be surprised by high-level supply line problems.

The best option here is to utilize robust Enterprise Resource Planning (ERP), Storage Resource Management (SRP), and Customer Relationship Management (CRM) databases which are universally accessible.

3. Implement AI oversight

AI in industry is a developing business, but at the moment AI is already able to oversee manufacturing processes with an attention to detail beyond what human overseers can manage. An AI can theoretically oversee every valve and line in a conveyor belt - for example - and instantly notice if any of the values fall outside set tolerances. This leads to fewer disruptions, since small problems can be spotted and fixed before they become big problems.

AI can also be deployed in a predictive capacity, analyzing manufacturing and purchasing trends. This allows it to make highly granular recommendations for purchasing and stocking, avoiding over- or under-stocks, and generally improving efficiency across the operation.

4. Maintain good communications

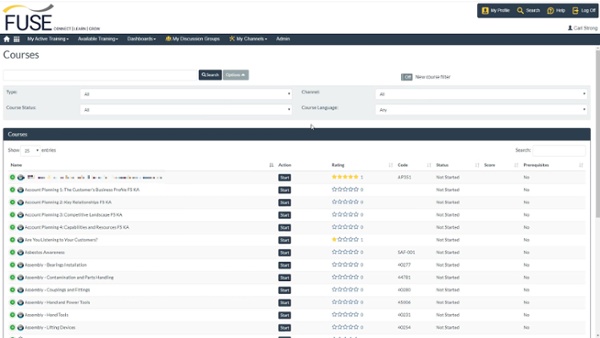

Communication is a must throughout any sort of large-scale upgrade process, and afterward. You want a communications and training platform in place which can be accessed by every participant in your ecosystem. This helps keep a global supply chain 'on the same page' while making it easier to train\onboard users for the new system.

LogicBay specializes in solving these communications issues! We've helped some of the largest companies in the world streamline their global ecosystems, and improve internal communication and training throughout. Contact us to learn more.